Embarking on the Gaggiuino project is an exciting step for any coffee enthusiast looking to elevate their Gaggia Classic from a good machine to a great one. This open-source modification promises unprecedented control over temperature, pressure, and flow, rivaling machines that cost thousands more. However, before you can enjoy that perfectly profiled shot, you must face a fundamental decision that defines your entire build process: will you use a custom Printed Circuit Board (PCB) or opt for traditional point-to-point (P2P) wiring? This choice impacts the difficulty, cost, and reliability of your installation. This article will serve as your guide, delving into both methods, exploring their respective advantages and disadvantages, and helping you choose the best path for your skills and goals.

The Gaggiuino challenge: Connecting the components

At its heart, the Gaggiuino is an electronics project. The goal is to integrate a microcontroller, like an STM32 Blackpill, into your Gaggia Classic. This “brain” needs to connect to various new components: a pressure transducer, temperature sensors (thermocouples), a solid-state relay (SSR) to control the boiler, a dimmer module for the pump, and a display screen for user interface. The success of the entire project hinges on making these connections correctly and reliably.

This is where the core debate begins. How do you physically link all these parts? Every component has multiple pins, and each pin must be wired to a specific destination on the microcontroller or another part. A single misplaced wire can lead to malfunctions or, in a worst-case scenario, damage to your components. The method you choose to create this web of connections is arguably the most critical decision in the entire build process, setting the stage for either a smooth assembly or a frustrating troubleshooting nightmare.

The classic route: Point-to-point wiring

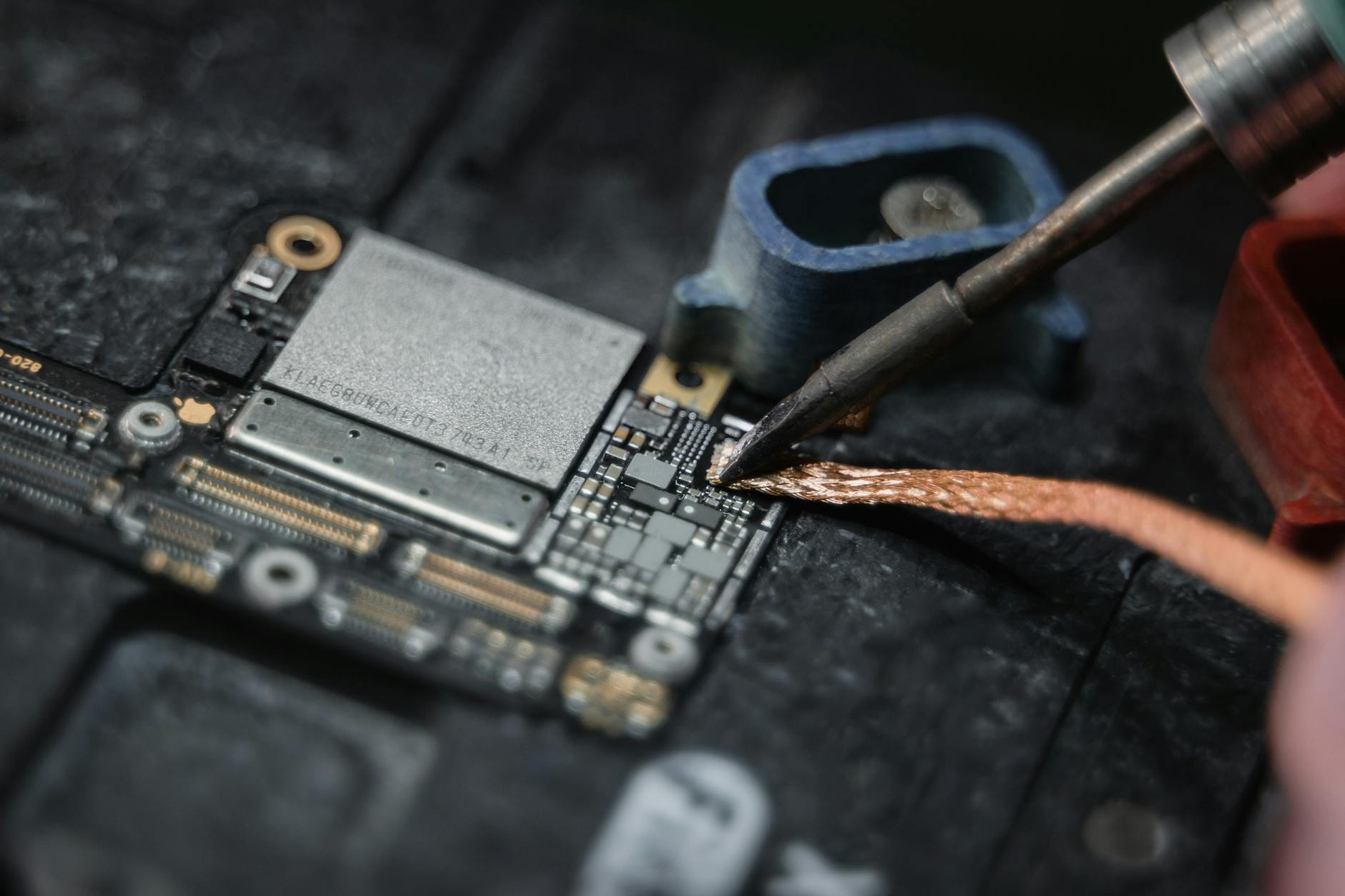

Point-to-point wiring is the traditional, hands-on approach to electronics. It involves manually cutting, stripping, and soldering individual wires to connect each component pin directly to its destination. Think of it as drawing the circuit diagram with physical wires. While it can be done neatly on perfboard, it often results in what hobbyists affectionately call a “rat’s nest” of wiring if care is not taken.

This method has several distinct advantages:

- Low cost: The primary appeal is budget. You don’t need to purchase a custom-made board; your main costs are a spool of wire, a soldering iron, and basic supplies.

- Ultimate flexibility: You are not constrained by a pre-designed layout. If you want to use a slightly different component, add a unique feature, or change the placement of parts, you can easily adapt your wiring plan.

- Educational value: There is no better way to understand how a circuit works than by building it one connection at a time. This path forces you to learn the fundamentals and gives you an intimate knowledge of your machine.

However, the P2P approach carries significant drawbacks. It is incredibly time-consuming, and the risk of error is high. A single forgotten connection or a poorly soldered joint can take hours to diagnose within a complex web of wires. Furthermore, the completed assembly is often less robust. The vibrations from the machine’s pump can cause wires to fatigue or connections to come loose over time, leading to reliability issues down the line.

The modern solution: The Printed Circuit Board (PCB)

The PCB represents a more modern, streamlined, and increasingly popular approach for Gaggiuino builders. A PCB is a board that has the electrical connections, or “traces,” pre-printed onto its surface. Instead of wiring components together, you simply solder each component into its designated, clearly labeled spot on the board. The PCB handles all the complex connections for you.

The benefits of using a PCB are compelling, especially for beginners:

- Speed and simplicity: Assembly is drastically faster. What could take a full day of P2P wiring can often be completed in a couple of hours with a PCB. It turns a complex wiring task into a “paint-by-numbers” soldering exercise.

- Reduced errors: Since all the connections are embedded in the board’s design, the single biggest source of error—mis-wiring—is virtually eliminated. This leads to a much higher chance of the system working correctly on the first try.

- Reliability and neatness: The final installation is incredibly clean and professional. Solder joints on a PCB are generally stronger and more secure, and the entire unit is far more resistant to vibration, ensuring long-term stability. Troubleshooting is also simpler, as you can usually rule out wiring faults immediately.

The main trade-off is the initial cost, as you must purchase the PCB from a community-approved vendor or have it manufactured. This also locks you into the specific components the board was designed for, offering less flexibility for customization than the P2P method.

Making the right choice for you

To decide which path is best, you need to honestly assess your skills, budget, and priorities. The choice is not just about technical preference; it’s about what you want to get out of the project. Do you want a learning experience, or do you want a finished product as efficiently as possible? The table below provides a direct comparison to help you decide.

| Feature | Point-to-Point (P2P) | Printed Circuit Board (PCB) |

|---|---|---|

| Cost | Lower initial cost (wire is cheap) | Higher initial cost (must buy the board) |

| Installation Time | Very long (many hours to a full day) | Fast (typically 1-3 hours) |

| Difficulty | High (requires patience and meticulous attention) | Low to moderate (basic soldering skills needed) |

| Error-Proneness | High risk of wiring mistakes | Very low risk of wiring mistakes |

| Troubleshooting | Extremely difficult | Much simpler |

| Reliability | Moderate (risk of loose connections over time) | High (robust and vibration-resistant) |

| Flexibility | Maximum (easy to modify and customize) | Low (locked into the board’s design) |

Ultimately, the P2P path is best suited for the experienced electronics hobbyist who enjoys the process of building from scratch and wants to customize their build, or for someone on the strictest of budgets. For the vast majority of builders, especially those new to electronics, the PCB route is the highly recommended choice. It minimizes frustration, maximizes the chance of success, and provides a reliable, professional-grade result that will stand the test of time inside your espresso machine.

In conclusion, the decision between a PCB and point-to-point wiring is a pivotal moment in your Gaggiuino journey. The P2P method offers a deep, hands-on educational experience with maximum flexibility at a minimal cost, but it demands significant time, patience, and a high tolerance for troubleshooting complex wiring. In contrast, the PCB path provides a streamlined, reliable, and efficient solution that dramatically reduces assembly time and the likelihood of errors. While it comes with a higher upfront cost and less room for customization, it is the most direct route to a stable, professionally finished machine. For most enthusiasts eager to unlock the Gaggiuino’s potential without getting bogged down in wiring complexities, the PCB is the clear and superior choice for a successful installation.

No products in the cart.

No products in the cart.